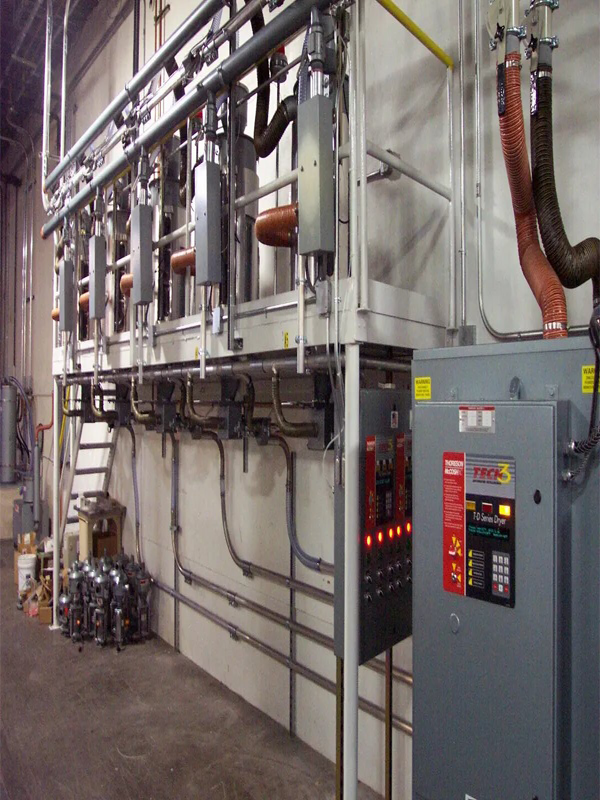

In industries that rely on compressed air systems, moisture in the air can cause a wide range of problems. Excess moisture can lead to rust, corrosion, and other damage to equipment, resulting in reduced efficiency and increased maintenance costs. This is where desiccant in-line air dryers come into play. These dryers are designed to remove moisture from compressed air systems, ensuring that the air is dry and suitable for sensitive applications.

What are Desiccant In-Line Air Dryers?

A desiccant in-line air dryer is a device that removes water vapor from compressed air by using desiccants, which are materials that attract and hold moisture. These dryers are placed directly into the air line, making them highly efficient at preventing moisture from reaching downstream equipment. The key benefit of using a desiccant-based system is that it can dry the air to a much lower dew point compared to other drying methods, such as refrigeration-based dryers.

Benefits of Using In-Line Desiccant Air Dryers

- Enhanced Equipment Longevity: Moisture can lead to corrosion, rust, and wear in equipment such as valves, cylinders, and pneumatic tools. By ensuring that the air is dry, in-line desiccant air dryers extend the lifespan of your equipment, reducing the need for repairs and replacements.

- Improved Efficiency: Moisture-laden air can cause a drop in efficiency by increasing the energy required to operate machinery. Desiccant air dryers improve the overall efficiency of your compressed air system by providing clean, dry air that enhances performance.

- Cost Savings: By preventing equipment damage and reducing energy consumption, in-line desiccant dryers can lead to significant cost savings. The upfront investment in a dryer pays off in the long run through lower maintenance costs and fewer equipment replacements.

- Versatility: These dryers can be used across a variety of industries, from manufacturing to pharmaceuticals. Any industry that requires clean, dry air to maintain equipment and product quality can benefit from inline desiccant air dryers.

How to choose an Air Line Desiccant Dryer Manufacturer

When looking for an air line desiccant dryer manufacturer, it’s essential to select a company with a strong reputation for quality and reliability. The right manufacturer will offer a range of products that meet your specific needs, from small-scale operations to larger industrial applications. They will also provide guidance on installation, maintenance, and replacement parts to ensure that your air dryer system operates efficiently over time.

In conclusion, desiccant in-line air dryers are vital for any compressed air system that needs dry, moisture-free air. They provide significant benefits, including extending equipment life, improving efficiency, and saving costs, making them an essential investment for many industries.