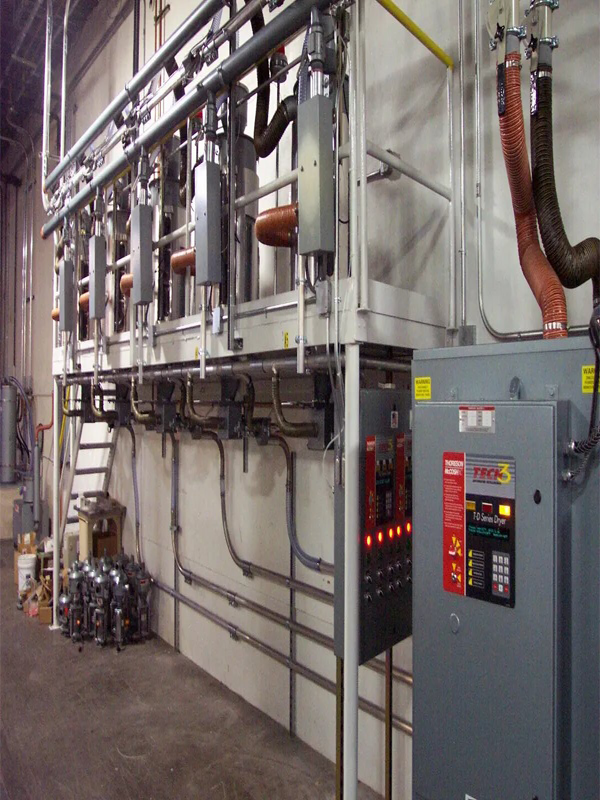

Thermal desiccant dryers are indispensable in industrial operations that require high-quality, moisture-free compressed air. These systems play a vital role in maintaining equipment performance, ensuring process efficiency, and extending the longevity of sensitive machinery across diverse industries.

What Are Thermal Desiccant Dryers?

Thermal desiccant dryers are advanced systems engineered to extract moisture from compressed air. Using desiccant materials that absorb water vapor, these dryers employ heat to regenerate the desiccant, releasing the trapped moisture and maintaining continuous drying cycles. This process produces exceptionally dry air suitable for the most demanding applications where moisture could compromise operations.

Types of Thermal Desiccant Dryers

Thermal desiccant dryers are available in different configurations, each designed to address specific industrial needs:

1. Heated Desiccant Dryers

These Heated Desiccant dryers use an external heat source to regenerate the desiccant material. Known for their energy efficiency, they are ideal for high-volume operations. By relying on external heating, they minimize the amount of purge air required during regeneration, effectively reducing energy costs while delivering consistent performance.

2. Heatless Desiccant Dryers

Heatless systems regenerate the desiccant using a portion of the dried compressed air. While they are simpler in design and suitable for smaller setups, they tend to consume more compressed air during the regeneration process compared to heated systems, making them more suitable for specific, lower-demand applications.

3. Blower Purge Desiccant Dryers

Blower purge models utilize a blower and external heaters to regenerate the desiccant without consuming the dried compressed air. These dryers are energy-efficient and particularly well-suited for applications requiring large volumes of dry air. Their design allows for optimal performance with reduced operational costs.

Key Considerations When Selecting a Thermal Desiccant Dryer Manufacturer

Choosing the right thermal desiccant dryer manufacturer is essential to ensure reliability, efficiency, and tailored solutions for your specific requirements. Important factors to evaluate include:

- Product Reliability: Look for systems designed for durability and consistent performance in demanding environments.

- Energy Efficiency: Opt for dryers that minimize energy consumption without compromising air quality.

- Comprehensive Support: Manufacturers that offer robust technical assistance and maintenance services can help ensure long-term operational success.

Companies like Thoreson McCosh specialize in producing high-quality thermal desiccant dryers tailored to diverse industrial applications. Their solutions are engineered for superior performance, helping businesses reduce operational costs while achieving optimal air quality.