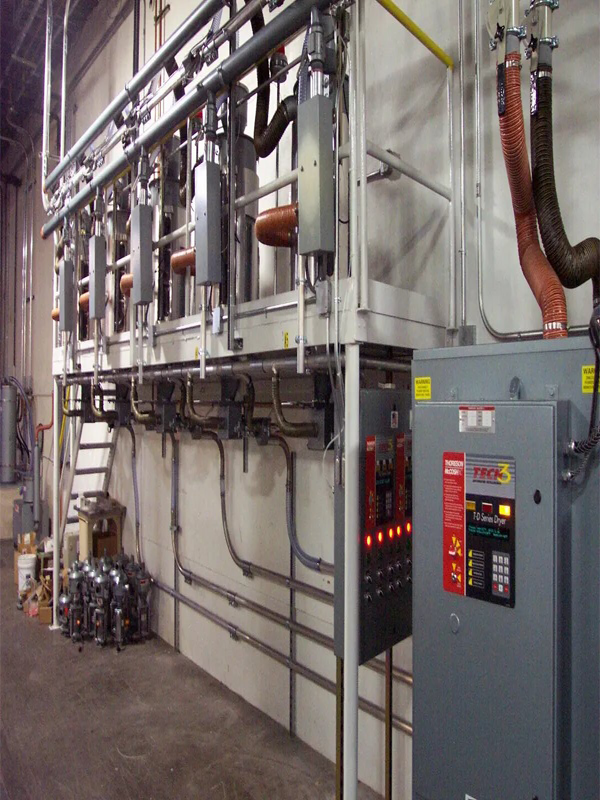

A desiccant air dryer for compressed air is essential for industries where moisture in compressed air can lead to equipment damage, corrosion, and product contamination. This type of dryer ensures that compressed air is clean, dry, and reliable, which is crucial for maintaining the integrity of machinery and end products.

How Does a Desiccant Compressed Air Dryer Work?

A desiccant compressed air dryer operates by using a desiccant material, such as silica gel or activated alumina, to absorb moisture from the air. The system typically has two chambers: one for drying and one for regenerating the desiccant. As compressed air passes through the dryer, the desiccant material captures water vapor, leaving the air dry and safe for use in various applications like pneumatic tools, painting, and other industrial processes.

Types of Desiccant Compressed Air Dryers

When choosing a desiccant air dryer for compressed air, it’s crucial to understand the two primary types:

- Heatless Desiccant Dryer: This is the most commonly used type and does not require external heat for regeneration. Instead, it utilizes a portion of the dry compressed air to regenerate the desiccant material. The system alternates between drying and regeneration cycles, providing continuous operation without the need for additional heating.

- Heated Desiccant Dryer: In this model, external heat is applied to regenerate the desiccant, which reduces the amount of compressed air required for the regeneration process. This makes the heated desiccant dryer more energy-efficient over time, particularly in high-demand environments.

Key Benefits of a Desiccant Air Dryer for Compressed Air

- Prevents Corrosion: Moisture in compressed air systems can lead to rust and corrosion in pipes and machinery. A desiccant air dryer eliminates this risk by providing dry air.

- Protects Product Quality: In industries like food processing, pharmaceuticals, and electronics, dry air ensures the quality of products and prevents contamination.

- Increases Equipment Lifespan: Dry, moisture-free air reduces wear and tear on pneumatic tools and other sensitive machinery, leading to fewer repairs and extended equipment life.

Investing in a desiccant compressed air dryer enhances the efficiency and reliability of your compressed air system, ensuring optimal performance in industrial applications.