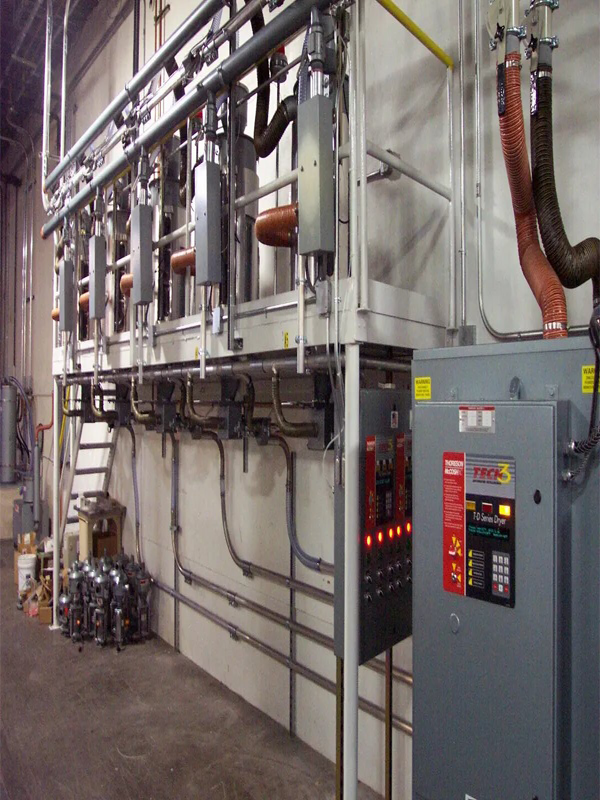

Compressed air systems are vital to numerous industries, but excess moisture in these systems can cause significant problems. Moisture leads to rust, corrosion, and damage to equipment, reducing efficiency and increasing maintenance costs. In-line desiccant air dryers offer a reliable solution by effectively removing moisture from compressed air, ensuring the air remains clean and dry for even the most sensitive applications.

What Are In-Line Desiccant Air Dryers?

In-line desiccant air dryers are specialized devices designed to extract water vapor from compressed air systems. They utilize desiccants—materials with a strong affinity for moisture—to achieve this. Installed directly in the air line, these dryers prevent moisture from reaching downstream equipment. Unlike other methods, such as refrigeration-based systems, desiccant dryers achieve significantly lower dew points, making them ideal for applications requiring exceptionally dry air.

Key Advantages of In-Line Desiccant Air Dryers

1. Prolonged Equipment Lifespan

Excess moisture can cause rust and wear in components like valves, pneumatic tools, and cylinders. By providing dry air, desiccant air dryers reduce corrosion risks and extend the longevity of your equipment, minimizing the need for frequent repairs or replacements.

2. Increased Operational Efficiency

Moist air can compromise machinery performance, demanding more energy for operation. By delivering clean, moisture-free air, in-line desiccant dryers enhance system efficiency, leading to smoother and more reliable operations.

3. Cost-Effective Maintenance

Preventing moisture-related damage reduces repair and replacement expenses. Additionally, the energy savings achieved through improved efficiency translate into significant long-term cost reductions.

4. Wide Application Range

From manufacturing plants to pharmaceutical facilities, in-line desiccant dryers are versatile and suitable for any industry requiring dry air to protect equipment and maintain product quality.

Choosing the Right Desiccant Air Dryer Manufacturer

Selecting the right manufacturer is crucial for obtaining reliable, high-quality desiccant air dryers. Look for companies with a proven track record of delivering durable and efficient products tailored to various needs, from small-scale operations to large industrial systems. A reputable manufacturer will also provide installation support, maintenance guidance, and replacement parts to keep your air drying system running optimally.

Why Invest in In-Line Desiccant Air Dryers?

In-line desiccant air dryers are indispensable for maintaining the integrity of compressed air systems. They prevent moisture-related issues, enhance equipment performance, and reduce operational costs, making them an essential asset across industries. With the right dryer in place, businesses can protect their investments and ensure seamless, efficient operations.