In the vast and technical world of industrial vacuum systems, Thoreson McCosh has established itself as a pinnacle of innovation and reliability. As a renowned vacuum pump filter manufacturer, the company offers an extensive range of vacuum pump units and vacuum pump enclosures designed to meet the diverse needs of industries ranging from plastics processing to chemical manufacturing. The benefits and advantages of their systems are numerous, showcasing why Thoreson McCosh stands out in the industrial vacuum system landscape.

Comprehensive Solutions from a Trusted Vacuum Pump Filter Manufacturer

Quality and Efficiency: Thoreson McCosh’s vacuum pump filters are engineered with precision, aiming to enhance the operational efficiency of vacuum systems while extending their lifespan. The filters are designed to prevent contaminants such as dust, particles, and vapors from entering the vacuum pump, which are critical in maintaining the purity of the process and protecting the machinery from damage. This meticulous attention to detail in filter design not only safeguards the equipment but also ensures consistent performance under rigorous industrial conditions.

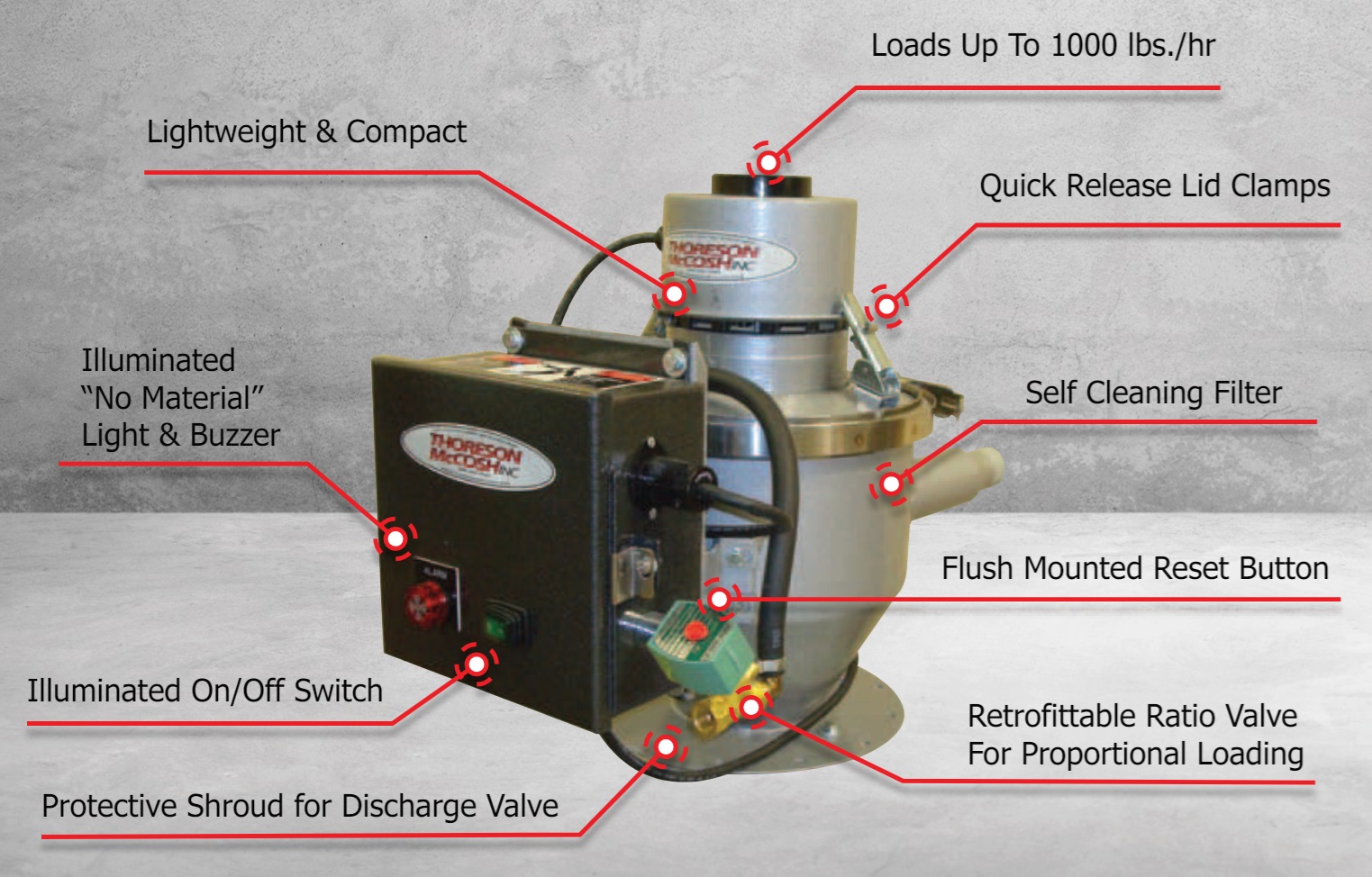

Customizable Vacuum Pump Units: Thoreson McCosh’s vacuum pump units are a testament to the company’s commitment to versatility and customer satisfaction. Each unit can be customized to fit specific requirements, offering variations in horsepower, flow rate, and vacuum level. Whether for light or heavy-duty applications, these units maintain optimal performance, thanks to their robust construction and the integration of top-tier vacuum pump filters. The adaptability of Thoreson McCosh’s equipment allows for seamless integration into existing systems, proving that one size does not fit all when it comes to industrial needs.

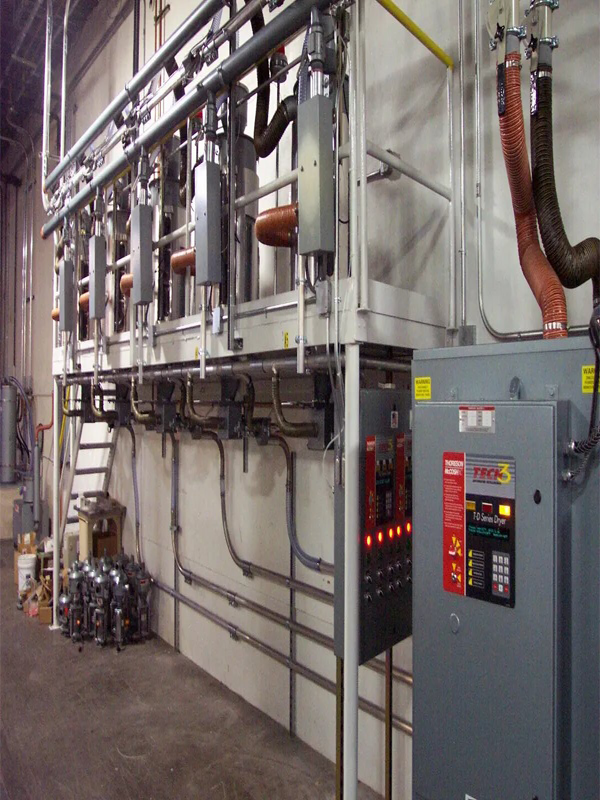

Enhanced Operational Safety with Vacuum Pump Enclosures: Noise reduction and safety are paramount in industrial environments, and Thoreson McCosh’s vacuum pump enclosures are designed to address these concerns effectively. These enclosures not only suppress the noise produced by vacuum pumps but also add an extra layer of protection against environmental factors and mechanical impacts. Constructed from durable materials, these enclosures ensure that the vacuum units are well-protected, which minimizes downtime and maintenance costs. Furthermore, the ergonomic design of these enclosures facilitates easier access for maintenance personnel, enhancing overall safety and convenience.

Advantages of Opting for Thoreson McCosh

Superior Performance: The integration of high-quality vacuum pump filters within the units leads to a more efficient and reliable performance. These filters are capable of trapping even the smallest particles, thereby preventing the common problem of clogging and reducing the potential for maintenance issues down the line. With Thoreson McCosh’s products, industries benefit from a cleaner operation, reduced operational costs, and a longer service life of the vacuum pumps.

Energy Efficiency: Thoreson McCosh places a strong emphasis on energy efficiency. The company’s vacuum pump units are designed to operate at maximum efficiency, which not only conserves energy but also reduces utility costs significantly. By optimizing the performance through superior design and better filtration technology, these units maintain high standards of efficiency without compromising on power or effectiveness.

Customization and Flexibility: One of the standout features of Thoreson McCosh’s offerings is their ability to tailor products to specific industrial requirements. This flexibility ensures that every client receives a solution that is not only effective but also perfectly aligned with their operational needs. Whether adjusting the flow rate, customizing the enclosure, or selecting specific filters, Thoreson McCosh works closely with clients to ensure that the end product enhances their production process.

Durability and Reliability: Durability is at the heart of every Thoreson McCosh vacuum pump unit and enclosure. Made with high-quality materials and built to withstand the rigors of industrial use, these products promise longevity and reliability. The robust construction not only prevents physical damages and operational failures but also ensures that the units can operate in various environmental conditions without faltering.

Elevating Industrial Processes

The operational benefits of using Thoreson McCosh’s vacuum pump filters, units, and enclosures are clear. They not only improve the efficiency and safety of industrial vacuum systems but also contribute to longer operational life spans and reduced maintenance costs. Thoreson McCosh continues to lead as a vacuum pump filter manufacturer by setting standards in reliability, efficiency, and customer-centric solutions. The company’s dedication to quality and its innovative approach in designing customizable and flexible systems are what make it a top choice for industries looking to upgrade or install new vacuum systems.

Each product is a reflection of Thoreson McCosh’s commitment to excellence and its understanding of the dynamic needs of modern industries. By choosing Thoreson McCosh, businesses are not just purchasing a product; they are investing in a solution that will bring them substantial operational benefits and a competitive edge in their respective markets. As industries evolve and new challenges arise, Thoreson McCosh’s adaptable and forward-thinking products will undoubtedly continue to be invaluable assets for any industrial process requiring precise and efficient vacuum solutions.