In various industrial applications, the efficient removal of gases and unwanted substances is crucial for optimal performance. This is where vacuum pumps play a pivotal role. Among the plethora of options available in the market, the MK-Series Vacuum Pump by Thoreson McCosh stands out for its reliability, versatility, and performance.

What are Vacuum Pumps?

Vacuum pumps are devices designed to remove gas molecules from a sealed volume to create a partial vacuum. This process finds applications across industries such as manufacturing, pharmaceuticals, food processing, and more. By reducing the pressure within a closed system, vacuum pumps enable the efficient transfer, filtration, and manipulation of substances.

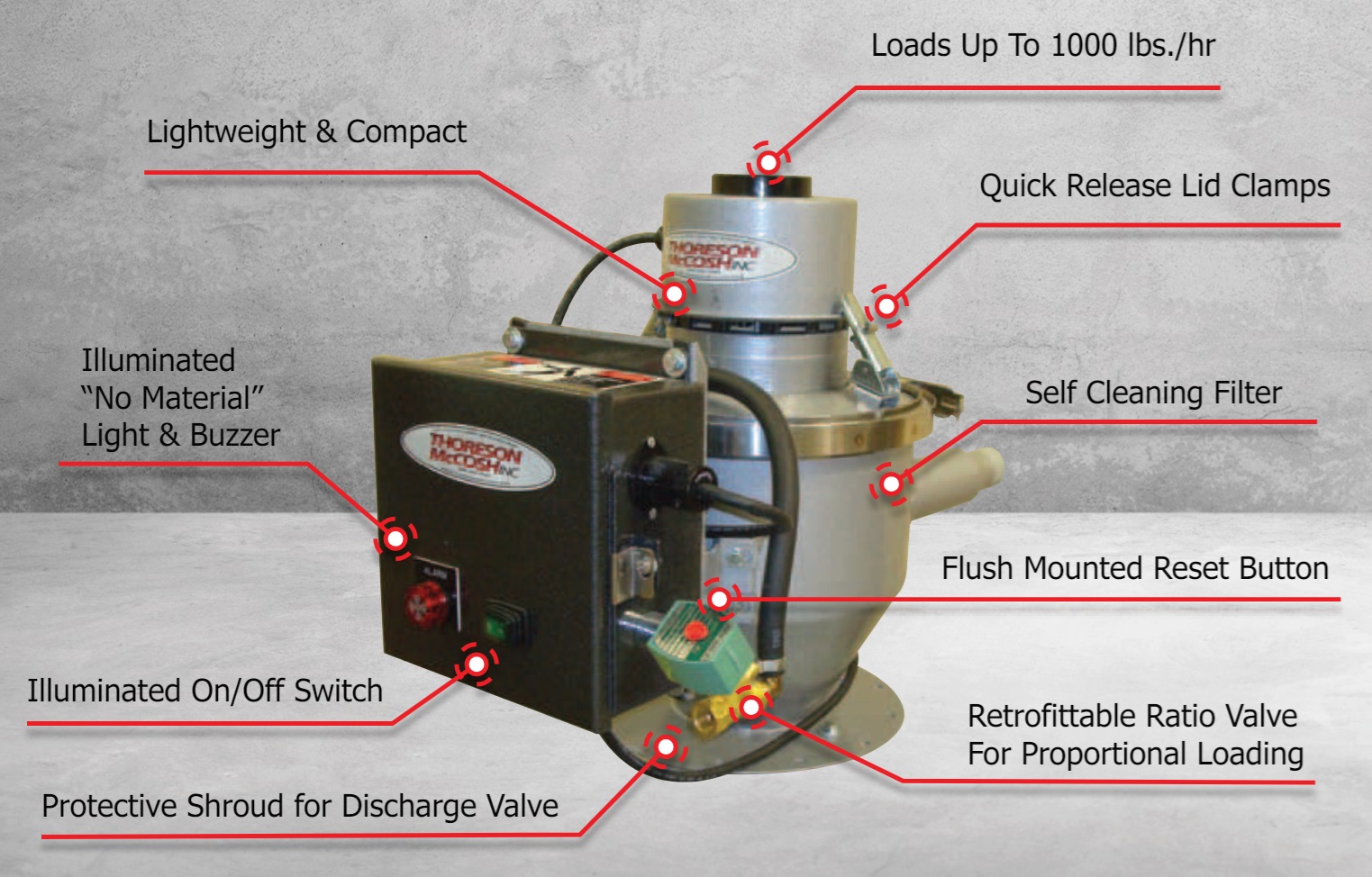

MK-Series Vacuum Pump: Key Features

Thoreson McCosh’s MK-Series Vacuum Pump is renowned for its cutting-edge technology and robust construction. Here are some key features that make it a preferred choice among professionals:

- High Performance: The MK-Series boasts impressive pumping speeds and ultimate vacuum levels, ensuring swift and efficient evacuation of air and gases from enclosures.

- Reliability: Built with durability in mind, Thoreson McCosh’s vacuum pumps are engineered to withstand demanding industrial environments, offering consistent performance over prolonged periods.

- Versatility: Whether it’s for laboratory applications, industrial processes, or research facilities, the MK-Series Vacuum Pump caters to a wide range of needs. Its adaptability makes it suitable for diverse applications, from degassing to vacuum drying.

- Energy Efficiency: With an eye towards sustainability, Thoreson McCosh has designed the MK-Series Vacuum Pump to optimize energy consumption without compromising performance. This not only reduces operational costs but also minimizes the environmental footprint.

- Ease of Maintenance: Featuring user-friendly design elements, such as accessible components and straightforward maintenance procedures, the MK-Series ensures minimal downtime and maximum productivity.

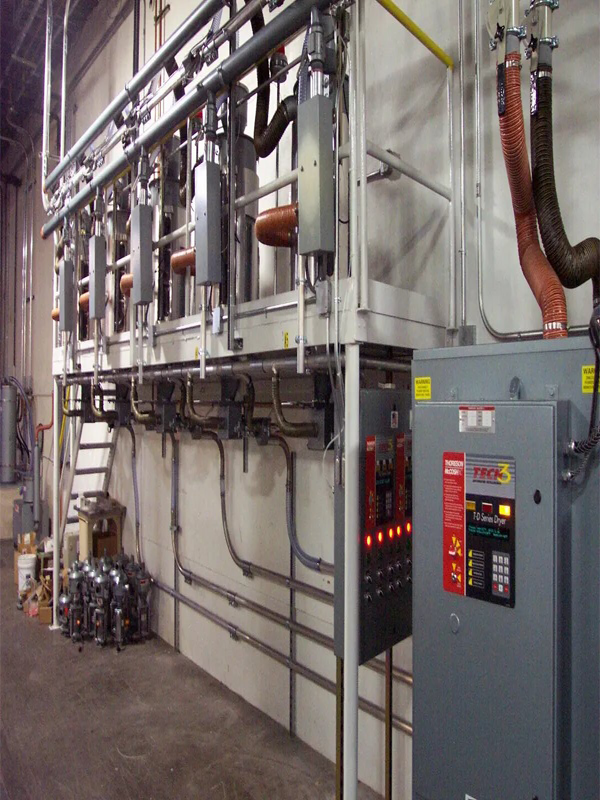

Enclosures: Enhancing Vacuum Pump Efficiency

In many applications, the effectiveness of vacuum pumps can be further enhanced by utilizing enclosures. Enclosures create a controlled environment, facilitating optimal vacuum conditions and preventing contamination or leakage.

Types of Enclosures

- Vacuum Chambers: These sealed containers provide a controlled environment for conducting experiments, processing materials, or testing components under vacuum conditions. Vacuum chambers come in various sizes and configurations to suit different applications.

- Glove Boxes: Often used in laboratories and cleanroom environments, glove boxes allow operators to handle sensitive materials or substances under vacuum or inert gas atmospheres. They provide a barrier between the user and the enclosed environment, ensuring safety and precision.

Portable Vacuum Pumps: On-the-Go Solutions

In certain scenarios where mobility is essential, portable vacuum pumps offer a convenient solution. Whether it’s fieldwork, on-site repairs, or remote operations, these compact devices provide the flexibility to create vacuum conditions wherever needed.

Thoreson McCosh understands the importance of portability and offers a range of portable vacuum pumps that combine performance with convenience. Designed for ease of transport and quick setup, these pumps ensure reliable vacuum generation in diverse settings.