In the dynamic landscape of modern manufacturing, efficiency is paramount. Thoreson McCosh recognizes this demand and offers innovative solutions like Tornado Material Loaders to streamline material handling processes. With a focus on efficiency, reliability, and versatility, these loaders are transforming the way manufacturers approach material transfer tasks.

Tornado Compressed Air Loader: Powering Efficiency

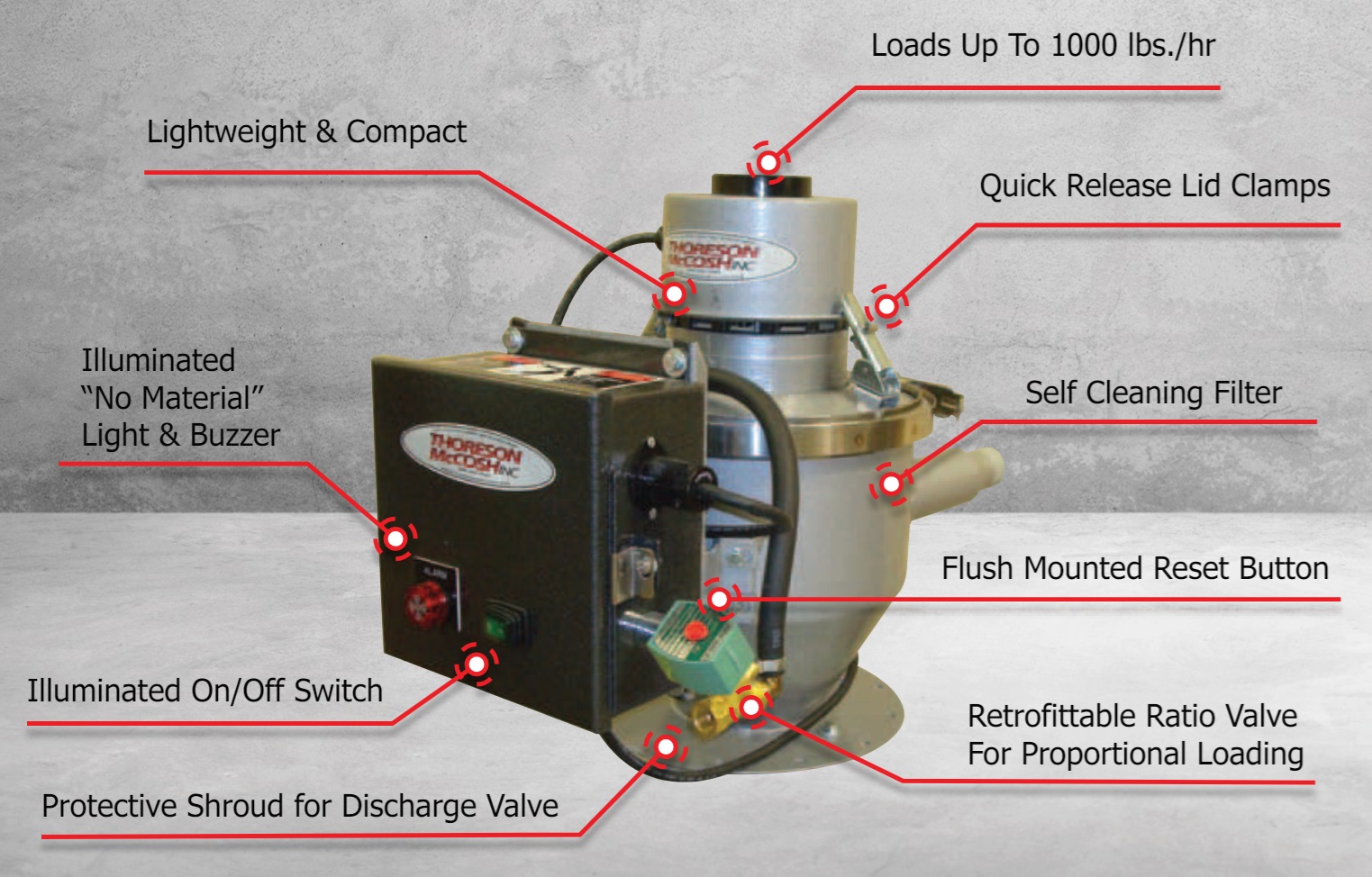

The Tornado Compressed Air Loader stands out as a flagship model in Thoreson McCosh’s lineup. Harnessing the power of compressed air, this loader creates a potent vacuum force, enabling rapid and precise material transfer. By eliminating complex mechanical components, the Compressed Air Loader reduces maintenance requirements and enhances reliability, making it an ideal choice for industries where uptime is critical.

VM-Series Loaders: Versatility Redefined

The VM-Series Loaders offer unparalleled versatility, combining pneumatic conveying efficiency with modular design flexibility. These loaders seamlessly integrate into existing production lines, providing consistent performance and precise material flow control. Whether handling plastic pellets, granules, or powders, VM-Series Loaders deliver reliable operation and adaptability to diverse material handling challenges.

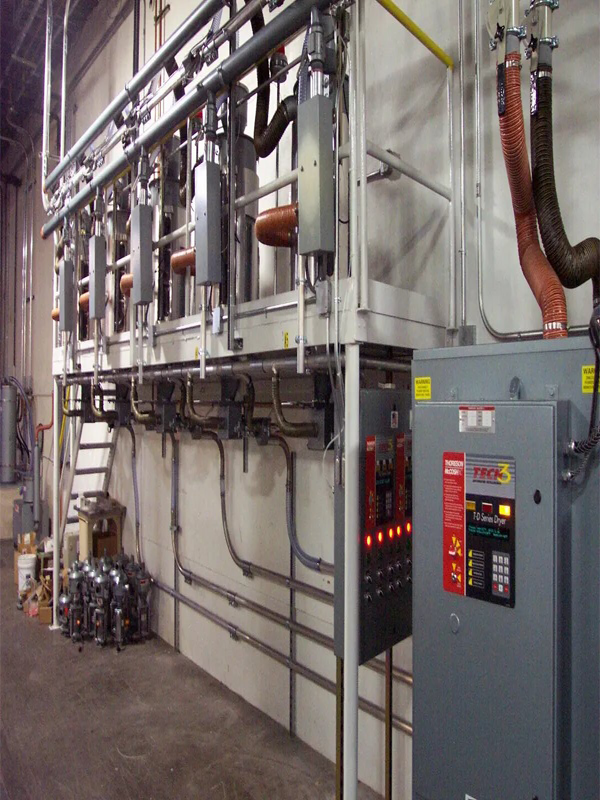

Efficiency in Action: Tornado Material Loaders in Operation

Tornado Material Loaders excel in adapting to various material types, from abrasive granules to delicate powders. Advanced filtration systems ensure product quality by preventing contaminants from entering processing equipment. Moreover, user-friendly interfaces and intuitive controls streamline operation, reducing the need for extensive training and minimizing the risk of errors.

Enhanced Safety and Convenience

Safety is paramount in manufacturing environments, and Tornado Material Loaders are designed with operator safety in mind. Built-in safety features ensure workplace safety, providing peace of mind for operators and supervisors. Additionally, by automating material handling processes, these loaders free up valuable manpower, allowing personnel to focus on higher-value tasks.

Comprehensive Support from Thoreson McCosh

Thoreson McCosh is committed to providing comprehensive support for its Tornado Material Loaders. From installation and commissioning to ongoing maintenance and technical assistance, their team of experts ensures the optimal performance of every loader. By partnering with Thoreson McCosh, manufacturers can leverage their expertise to maximize the efficiency and reliability of their material handling operations.