In the ever-evolving landscape of industrial manufacturing, the importance of maintaining a controlled environment cannot be overstated. Moisture and particulate contamination can significantly impair the functionality and longevity of equipment, leading to costly downtime and reduced productivity. Thoreson McCosh, a leader in Desiccant Dryers and vacuum technology, offers cutting-edge solutions that address these challenges head-on. In this content, we delve into the specifics of their offerings, including Desiccant In-line Vacuum Pump Filters, Vacuum Pump Enclosures, and Portable Vacuum Pumps, showcasing how these innovations are setting new standards in efficiency and reliability.

Revolutionizing Moisture Control: Desiccant In-line Vacuum Pump Filters

In the quest to protect sensitive equipment from the detrimental effects of moisture, Thoreson McCosh has pioneered the Desiccant In-line Vacuum Pump Filter Manufacturer segment. This innovative solution integrates seamlessly with vacuum systems to eliminate moisture before it can compromise the pump’s efficiency or damage the system’s internal components. By using highly effective desiccants, these filters provide superior moisture absorption, ensuring that air drawn into the vacuum pump is dry and free from contaminants.

What sets Thoreson McCosh’s desiccant filters apart is their unparalleled efficiency in moisture removal, coupled with their ease of maintenance and longevity. Designed to cater to a wide range of industrial applications, these filters are an indispensable tool for businesses looking to enhance their operational reliability and extend the lifespan of their vacuum pumps.

Enhancing Operational Integrity: Vacuum Pump Enclosures

Noise pollution and environmental contaminants pose significant challenges in industrial settings, where vacuum pumps are often a critical component of the production process. Thoreson McCosh’s Vacuum Pump Enclosures are ingeniously designed to address these issues. These enclosures not only significantly reduce noise levels, making for a more pleasant and compliant working environment, but they also protect the vacuum pumps from dust, debris, and other environmental contaminants that can lead to premature wear and failure.

Crafted from high-quality materials and engineered to ensure easy access for maintenance and monitoring, these enclosures are a testament to Thoreson McCosh’s commitment to enhancing the operational efficiency and longevity of vacuum systems. Whether in harsh industrial environments or more controlled settings, these enclosures provide an extra layer of protection that can make a substantial difference in the performance and reliability of vacuum pumps.

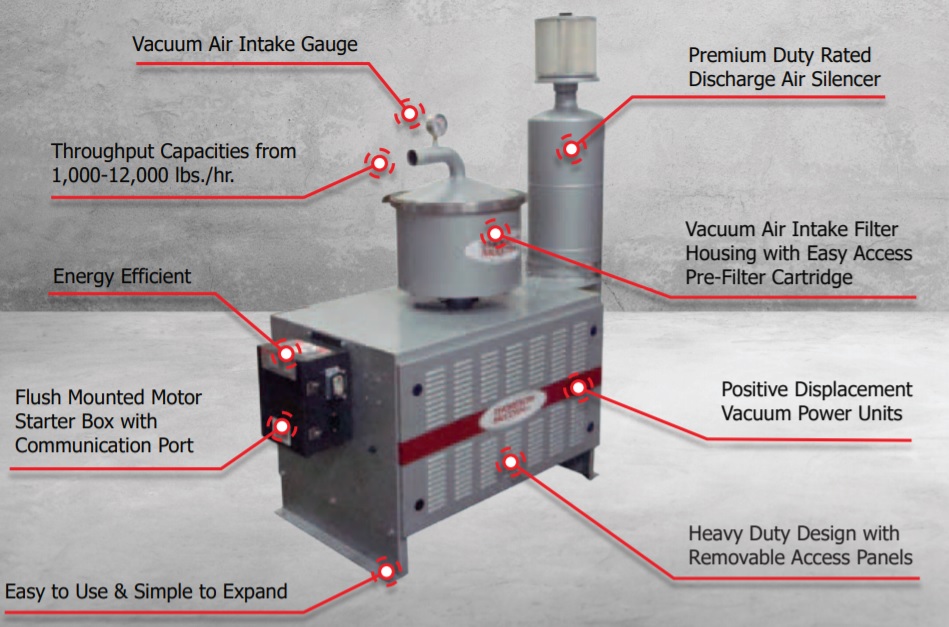

Mobility Meets Performance: Portable Vacuum Pumps

In many industrial applications, the need for mobility and flexibility cannot be overstated. Thoreson McCosh has risen to this challenge by offering Portable Vacuum Pumps that combine the performance and reliability of their stationary counterparts with the convenience of portability. These compact, yet powerful units are designed to meet the demands of various applications, from material handling and packaging to laboratory settings where mobility can significantly enhance operational efficiency.

The portability of these vacuum pumps opens up new avenues for businesses to optimize their operations. With easy-to-use interfaces and minimal maintenance requirements, Thoreson McCosh’s portable vacuum pumps are a perfect blend of functionality and convenience, offering businesses the flexibility to adapt their processes without compromising on performance or reliability.

Setting New Standards in Industrial Efficiency

Thoreson McCosh’s dedication to innovation is evident in their range of products, including Desiccant In-line Vacuum Pump Filters, Vacuum Pump Enclosures, and Portable Vacuum Pumps. By addressing critical challenges such as moisture control, noise pollution, and the need for mobility, Thoreson McCosh is not just providing solutions; they are setting new standards in industrial efficiency and reliability. As industries continue to evolve and demand more from their equipment, Thoreson McCosh stands ready to meet these challenges, offering products that enhance operational efficiency, protect investments, and ensure the smooth running of processes. For businesses looking to stay ahead in the competitive landscape of industrial manufacturing, partnering with Thoreson McCosh is a step towards a more efficient, reliable, and productive future.