In the dynamic world of plastics manufacturing, the efficiency of material handling can significantly affect productivity and profitability. Thoreson McCosh has been a pioneer in providing innovative solutions to streamline the processes involved in plastic resin handling. Among their standout offerings are the Self-Contained Vacuum Loaders, designed to enhance the operational flow within plastic processing facilities. These units embody reliability and precision, tailored to meet the high demands of the industry.

Understanding Self Contained Vacuum Loaders

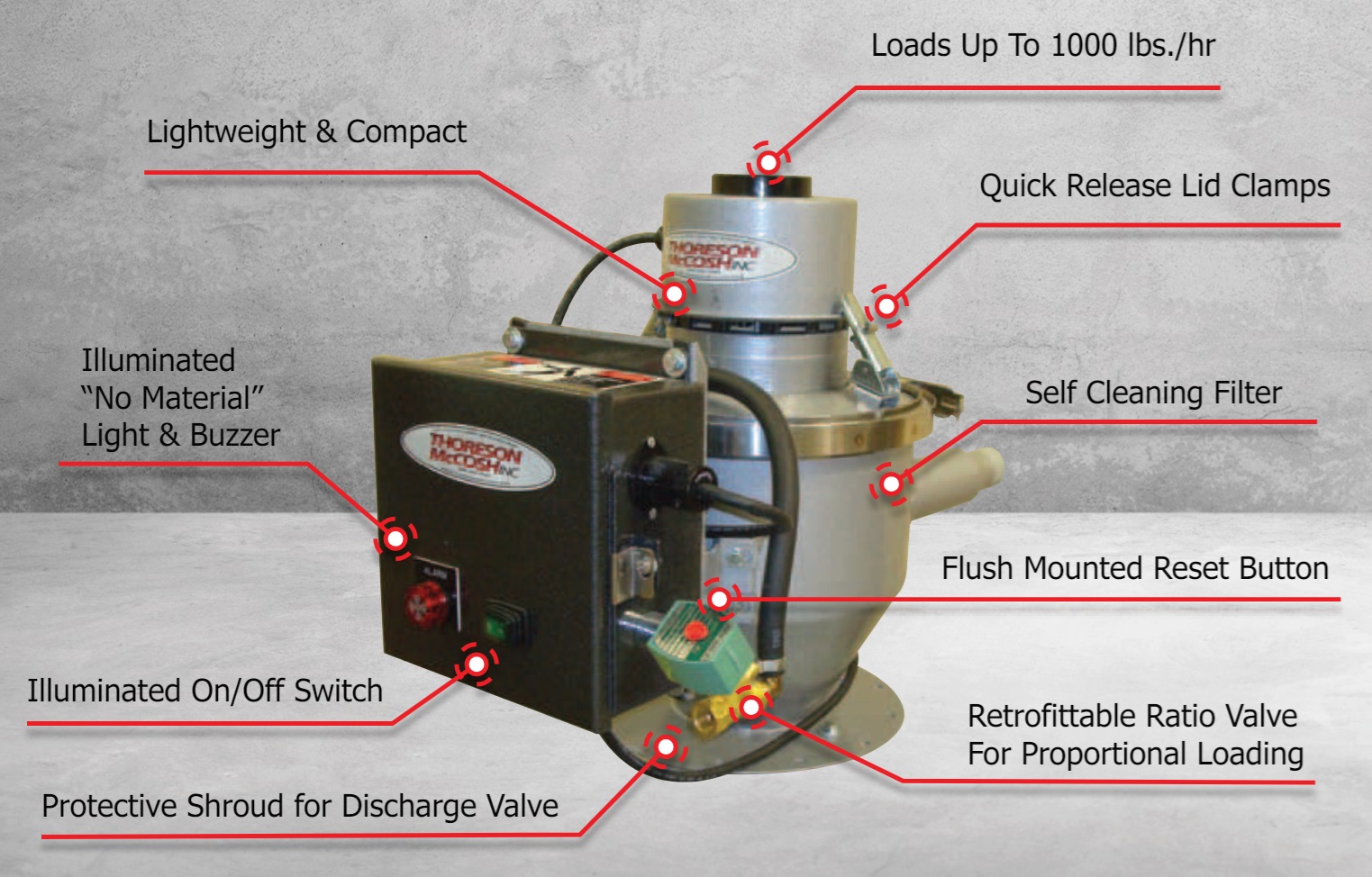

Self-Contained Vacuum Loaders are integral to managing and transporting plastic resins, which is a critical component in the manufacturing process. These loaders are engineered to convey granular or powdered plastics from storage to the processing machine. Unlike other systems that require a separate vacuum source, these loaders are equipped with their own built-in vacuum motor, which simplifies the installation and maintenance while providing a high level of performance.

The primary advantage of Vacuum Loaders lies in their compact design and ease of use. They eliminate the need for extensive piping systems, which not only reduces the initial installation cost but also decreases the likelihood of material wastage due to long-distance conveying. This efficiency is paramount in plants where space and resource optimization are crucial.

Key Features of Thoreson McCosh’s ML-Series Loaders

Thoreson McCosh’s ML-Series Loaders represent a significant advancement in vacuum loading technology. These units are specifically designed to handle a wide variety of materials, from powders to granules, with utmost precision. The ML-Series is characterized by its modularity, which allows for easy adaptation to different production requirements, and its user-friendly interface that ensures operators can manage processes swiftly and effectively.

One of the defining characteristics of the ML-Series Loaders is their robust construction. Built to withstand the rigors of continuous industrial use, these loaders feature stainless steel construction for the contact parts, ensuring durability and resistance to wear. Additionally, the loaders are equipped with advanced filtering systems that prevent material contamination and ensure clean, uninterrupted operation.

Innovations in Plastic Vacuum Receivers

Complementing the vacuum loaders are Thoreson McCosh’s Plastic Vacuum Receivers. These components are critical for the precise and controlled transfer of plastic resins from the loaders to the processing machines. The receivers are designed to be lightweight, yet durable enough to handle the abrasive nature of plastic materials. They are equipped with easy-to-clean filters and valves that ensure maintenance is straightforward and downtime is minimized.

The Vacuum Receivers work seamlessly with the Self Contained Vacuum Loaders to create a cohesive system that improves material flow and reduces the risk of blockages or material degradation. This is particularly important in applications where material purity is paramount, such as in medical or food-grade plastic production.

Application Across Industries

The versatility of Thoreson McCosh’s vacuum loading systems, including both the Self Contained Vacuum Loaders and the ML-Series, makes them suitable for a wide range of industries. These systems are not only beneficial for plastics but are also adaptable for use in the pharmaceutical, chemical, and food industries, where handling and conveying of powders and granules are critical.

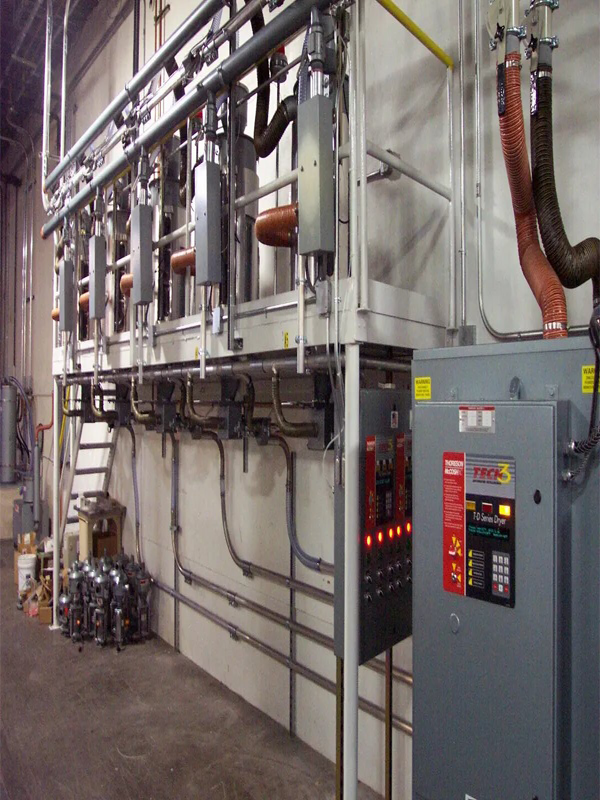

In the plastics industry, specifically, these loaders and receivers facilitate a smooth transition of materials from storage to the machine hopper without exposure to the external environment. This closed system transport minimizes the contamination risks and is essential for maintaining the quality of the end products.

Streamlining Operations with Thoreson McCosh

Thoreson McCosh continues to innovate in the field of material handling and conveying. Their Self Contained Vacuum Loaders and ML-Series Loaders are at the forefront of technology, offering both performance and reliability. Paired with their efficient Plastic Vacuum Receivers, these systems provide a comprehensive solution that promotes productivity and operational excellence in manufacturing facilities.

These advancements underscore Thoreson McCosh’s commitment to developing solutions that not only meet but exceed the evolving needs of the industries they serve. By integrating these sophisticated systems into their operations, manufacturers can achieve a significant reduction in material waste, enhanced operational efficiency, and ultimately, higher profitability.

In summary, whether upgrading an existing facility or designing a new plant, considering Thoreson McCosh’s state-of-the-art equipment should be a pivotal part of your material handling strategy. The efficiency and reliability of their Self Contained Vacuum Loaders, coupled with the innovation of the ML-Series Loaders and the effectiveness of Plastic Vacuum Receivers, create a system that significantly enhances the productivity and sustainability of manufacturing operations. As the industry continues to evolve, these tools will undoubtedly play a crucial role in shaping the future of plastics manufacturing. The journey towards optimized material handling is complex, yet Thoreson McCosh provides the necessary components to navigate this landscape successfully.